Water Treatment

Safe, reliable water plays a vital role in all our daily lives, keeping our community healthy, supporting our economy, and contributing to our overall quality of life. That’s why Cleveland Water has a comprehensive water treatment process in place to make sure our customers have access to safe, quality water every day.

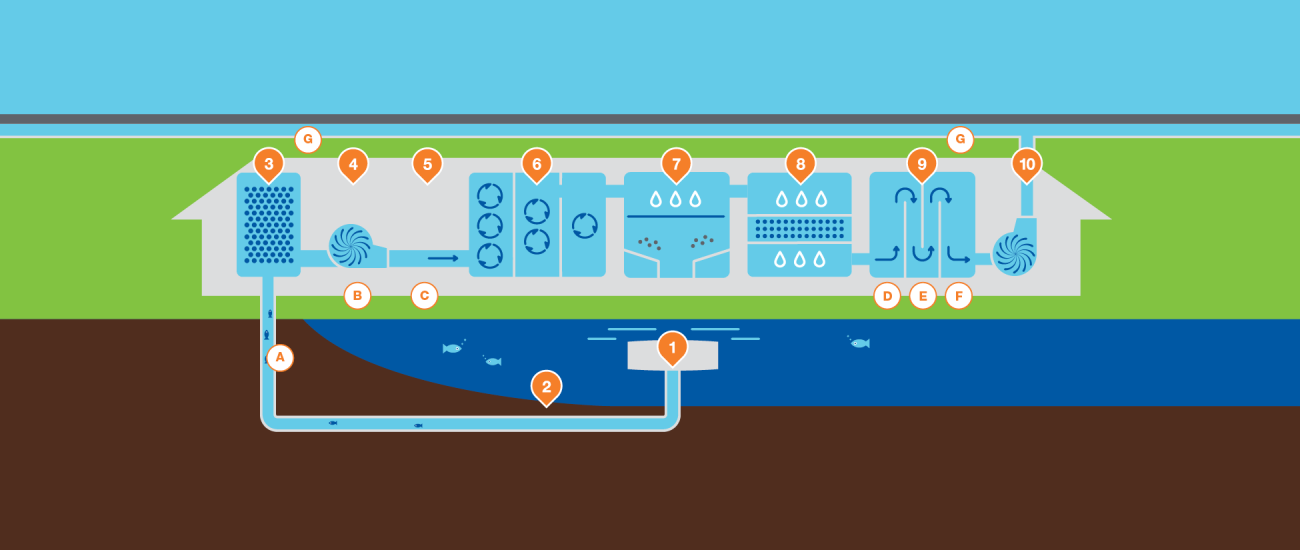

Our commitment to providing our customers with quality drinking water is proven through our treatment process. We use a conventional treatment process at all four of our plants to ensure our water meets federal and state requirements as well as the higher industry standards of the Partnership for Safe Water. This process involves the primary steps of coagulation, flocculation, sedimentation, filtration, disinfection, and finishing to take water from Lake Erie and turn it into clean, safe drinking water.

Go to:

Treatment Process Overview

Crib

Located 3 to 5 miles offshore in Lake Erie, a crib protects the top of the pipe into which lake water flows, preventing large pieces of debris from entering the pipe.

Intake Tunnel

Beneath the bed of Lake Erie, an intake tunnel, between 7 to 10 feet in diameter and several miles long, brings water to the treatment plant. Near the shore end of the tunnel, we add a chemical called Potassium Permanganate (A). Potassium Permanganate is an oxidant that helps more effectively remove particulates. It also helps control taste, odor, and color as well as quagga mussels and algae.

Screens

Screens filter out mussel shells, fish, and other large debris before the water enters the treatment process.

Raw Water Pumps

Raw water pumps pull in the water from Lake Erie to begin the treatment process. At the raw water pumps we add Powdered Activated Carbon (B). It absorbs organic material that can cause unpleasant tastes and odors. Contaminants attach themselves to the carbon granules and settle out in the sedimentation and filtration steps.

Rapid Mix

During the rapid mix step, Aluminum Sulfate (C), or Alum, is added and quickly mixed into the water. Alum is added as a coagulant to help small particles stick together so that they can be removed more easily.

Flocculation

Water moves through three zones of mixing, with each zone mixing at a slower speed than the one before to allow organic and inorganic material to clump together as floc.

Sedimentation

Water moves slowly through large settling basins where heavy clumps of floc settle to the bottom of the tanks and are removed. The cleaner water passes through the top of the tank to the next phase.

Filtration

At the filters, gravity pulls water through filter media made of two feet of anthracite over one foot of sand to remove finer impurities.

Disinfection & Finishing

At this step, we add Chlorine (D) – to kill pathogens, Fluoride (E) – to promote dental health, and Orthophosphate (F) – to prevent pipe corrosion. The water then slowly moves through the finished water reservoir to ensure chlorine has adequate time to kill all bacteria and viruses.

Finished Water Pumps

The finished water is pumped through the distribution system to customers. Throughout the treatment process, we test the water to make sure each stage is working effectively and only safe, clean water is produced and delivered to customers.

Water Treatment Plants

Baldwin Water Treatment Plant

The Baldwin Water Treatment Plant is located in the University Circle/Fairfax neighborhood. Put into service in 1925, it pumps an average of 71.1 million gallons of water a day to the residents and businesses located in downtown, University Circle, the east side of Cleveland, and the eastern and southeastern suburbs

Crown Water Treatment Plant

The Crown Water Treatment Plant is located in Westlake, making it the only water treatment plant not located in the City of Cleveland. The plant was first put into service in 1958 and pumps an average of 41.5 million gallons of water a day to the residents and businesses of Cleveland’s westside, including its western and southwestern suburbs.

Garrett Morgan Water Treatment Plant

The Garrett A. Morgan Water Treatment Plant, built in 1916, was constructed on the site of the city's first waterworks facility. It pumps an average of 60 million gallons of water a day to residents and businesses located downtown and in the western and southern suburbs of Cleveland.

Nottingham Water Treatment Plant

The Nottingham Water Treatment Plant is one of Cleveland Water’s four interconnected water treatment plants. Placed into service in September 1951, the plant pumps water to the eastern part of Cleveland and the southeastern suburbs.